Elegoo Neptune 3 Max Review

Elegoo Neptune 3 Max

The largest of the three available sizes in the third generation of Elegoo Neptune range of FDM printers, the Neptune 3 Max really does deliver on very large build volume whilst maintaining the core design, features, and reliability of the Neptune range.

Pros:

- Direct extrusion

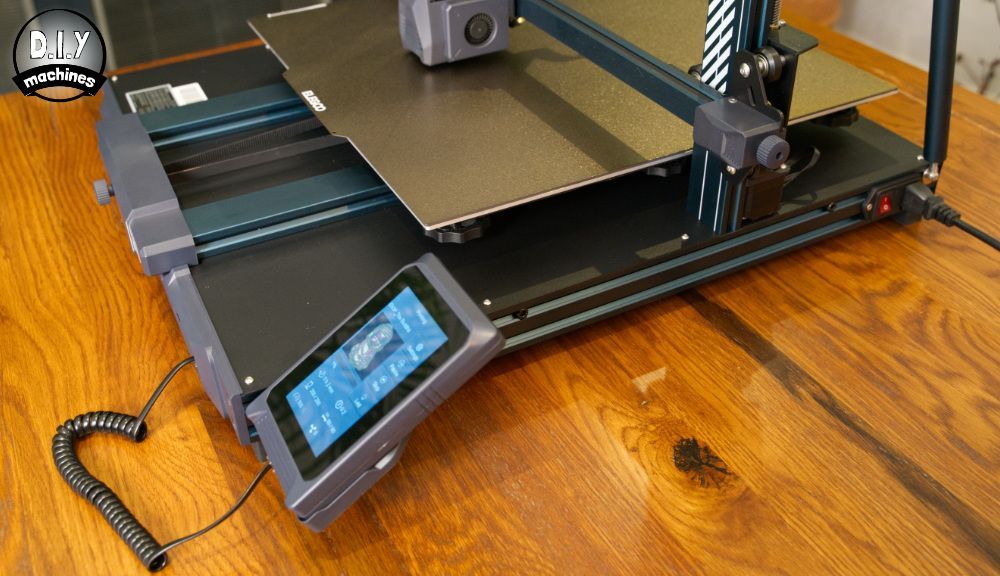

- Large, clear and simple controls

- New integrated LED lighting

- Power Outage Recovery

- 420 x 420 x 500mm build volume

Cons:

- A very large machine for most desktops

- Front mounted USB port

Where to buy:

- Amazon: Elegoo Neptune 3 Max

- 3D Jake (they have great stock levels): Elegoo Neptune 3 Max

What is it?

Elegoo's Neptune 3 Max is the largest version of the Neptune 3 Pro FDM 3D printer. There are two smaller versions of this printer - both of which have reviews if you're interested. They are the Neptune 3 Pro (the smallest) and the Neptune 3 Plus. I will write this as an independent review of the other machines, and where appropriate contrast where it defers from its two smaller siblings.

What is an FDM printer?

First up a brief description of a what a FDM printer actually is. FDM (Fused Deposition Modelling) printers have been found in domestic homes far longer than other 3D printing technologies such as resin based MSLA (Masked StereoLithogrAphy). As such their price continues to become more affordable and the technology is proven, refined and easy to work with. I cut my teeth on 3D printing with an FDM printer and mostly use them to this day.

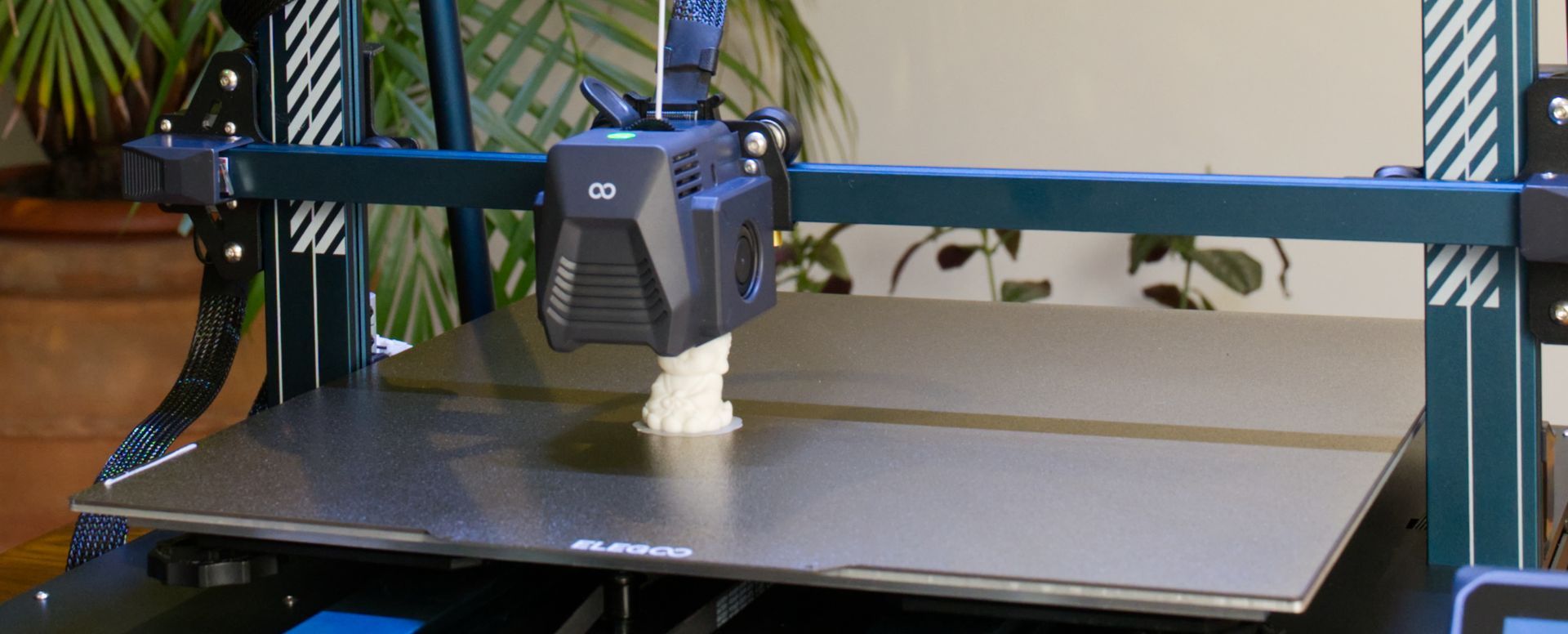

They work by 'slicing' the 3D computer model into thin horizontal slices, usually about 0.15 to 0.2mm high. Each slice is then extruded in molten plastic by the print head which draws one of these 2D slices onto the build platform before raising the nozzle height and proceeding with the next slice. As layer upon layer is laid down on top of the previous layer a 3D object is created. Voila.

The Technical Overview

| Printing Technology | FDM | |

|---|---|---|

| Print Volume | 420 x 420 x 500mm | |

| Layer height | 0.1 to 0.4mm | |

| Max. nozzle temperature | 260℃ | |

| Max. bed temperature | 100℃ | |

| Printable Filaments | PLA, ABS, PETG, TPU, TPE and infused (i.e wood, marble etc.) | |

| Extrusion Type | Direct Extrusion System |

The printers main selling point is its truly massive build volume. Boasting 420 x 420 x 500 it provides a massive 88,200cm³ of printing room. This more than 215% the Plus sizes 320x320x400mm volume and a staggering 549% the size of the Neptune 3 Pro's build volume of 16,065cm³ (its build volume measures 225 x 255 x280mm). A volume this size allow you to print truly large items as a single print, or many more smaller items without having to revisit your machine between prints.

The print bed , as so many are now, is both removable and magnetic. To detach a print, just wait for it to cool then bend the plate slightly - your print will pop right off. The surface is lightly textured which helps conceal the initial layers print lines.

The power supply is integrated inside of the base so no need to accommodate a bulky brick somewhere. Something new on this Max sized machine is the addition of a handy drawer built into its base. A very welcome addition and great place to store tools.

Print Volume

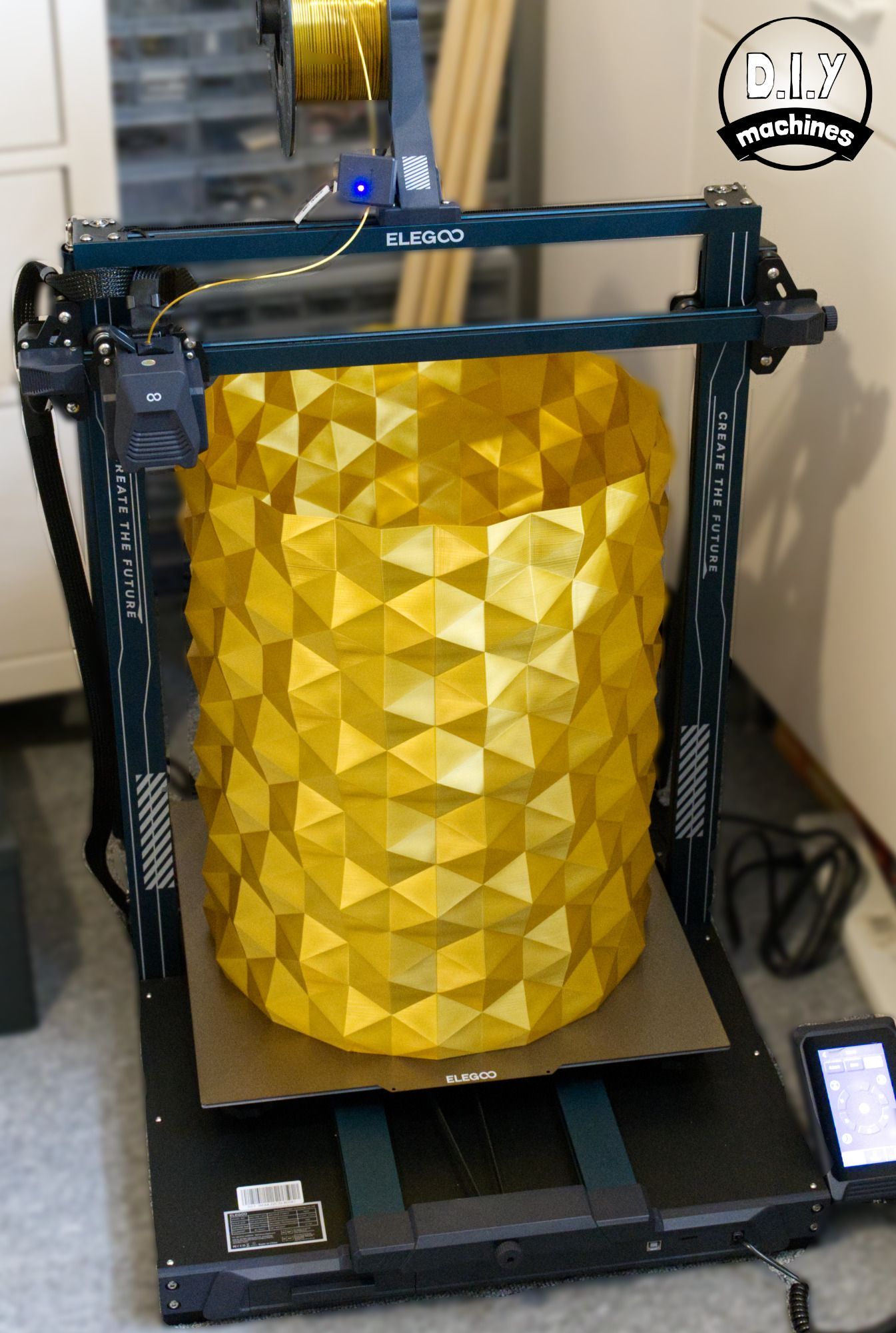

I couldn't mention the print volume without coming back to show you a couple of images to appreciate just how large it can print.

I'll tell you more about this specific print later in the review - but I wanted you to see the image now. To provide some scale I added a standard bottle of Pepsi (I was also thirsty so it had a dual purpose).

Integrated LED Lighting

One of the new features across the Neptune 3 line of printers is the integrated LED lights. These are found nestled inside the top gantry. I thought they would be gimmicky - when in fact I'm finding them very useful for illuminating the machine whilst preparing and actually printing the models.

When I find myself using one of my other printers without this feature I am reminded just how much the LEDs help when working in the vicinity of the machine.

Connectivity

The power switch and kettle lead connections are mounted on the right side towards the rear of the machine. The USB and memory card slot is mounted on the front of the machine. I personally think that this a great spot for the memory card slot but I prefer the USB port on the side and failing that the rear. This is because I think it is less prone to damage when the machine is connected to a computer for direct printing. I often set-up a Raspberry Pi running OctoPrint to manage my printers and this connects to your printer via USB.

Extruder

The Neptune 3 series of Elegoo printer all the utilise the same direct drive extrusion system. This is my preferred method of extrusion over the use of a Bowden Tube.

Pros:

- Increased ability to print with flexible filaments.

- Better print quality through constant extrusion control.

- Faster retraction.

- Simpler extrusion path.

Cons:

- Reduced print speeds because of slightly heavier print head.

- More elaborate print head design required.

Unlike most Direct Drive setups though. Elegoo have kept the filament sensor attached to the frame of the machine instead of the print head.

Having used the same sensor setup on the Neptune 3 Pro for a little while I now prefer this for several reasons; it reduces complexity of the print head, provides the system with earlier warning of filament run-out, and holds the filament strand whilst unloading/loading the print head preventing it from quickly knotting your spool of nicely pre-wound filament if you inadvertently let the end of the spool go.

The printer features auto-levelling to compensate for any undulations in the print surface. The printer takes no less than 63 readings across the entire print surface to create a digital map of the surface which it then uses to adjust the printing height as it moves around the platform. Should the compensation required be too drastic there are large knobs placed on the underside of the platform in six locations. (Three along each side). This will allow you to manually remove most of the unevenness before the printer then re-runs its levelling procedure to make final adjustments automatically.

Power Recovery

The power outage recovery feature is now becoming common place on any printers. This is certainly welcome on a machine with such a large print volume as it's likely to need to print for days when printing the largest of items. It would be a disaster if a power cut ruined a multiple-day print towards the end.

The power recovery feature will detect power interruptions and offer to re-heat the bed and nozzle before resuming where it was before the power failed. The main drawback of this feature is that it only work when at least 10mm of the print has already been completed - I assume this helps ensure the print it continues with is unlikely to have warped whilst cooling. However, you are still at the mercy of whether the print detached itself from the print bed as the surface cooled - which is what it is designed to do in normal circumstances.

Integrated Drawer

This is exclusive to the Neptune 3 Max - probably because of the large amount of space available in the base of the machine. The pull out drawer can fit all the tools I use day to day and for 98% of maintenance tasks in the future. It's not deep enough to house the glue stick but I have never used those with my 3D printer anyway.

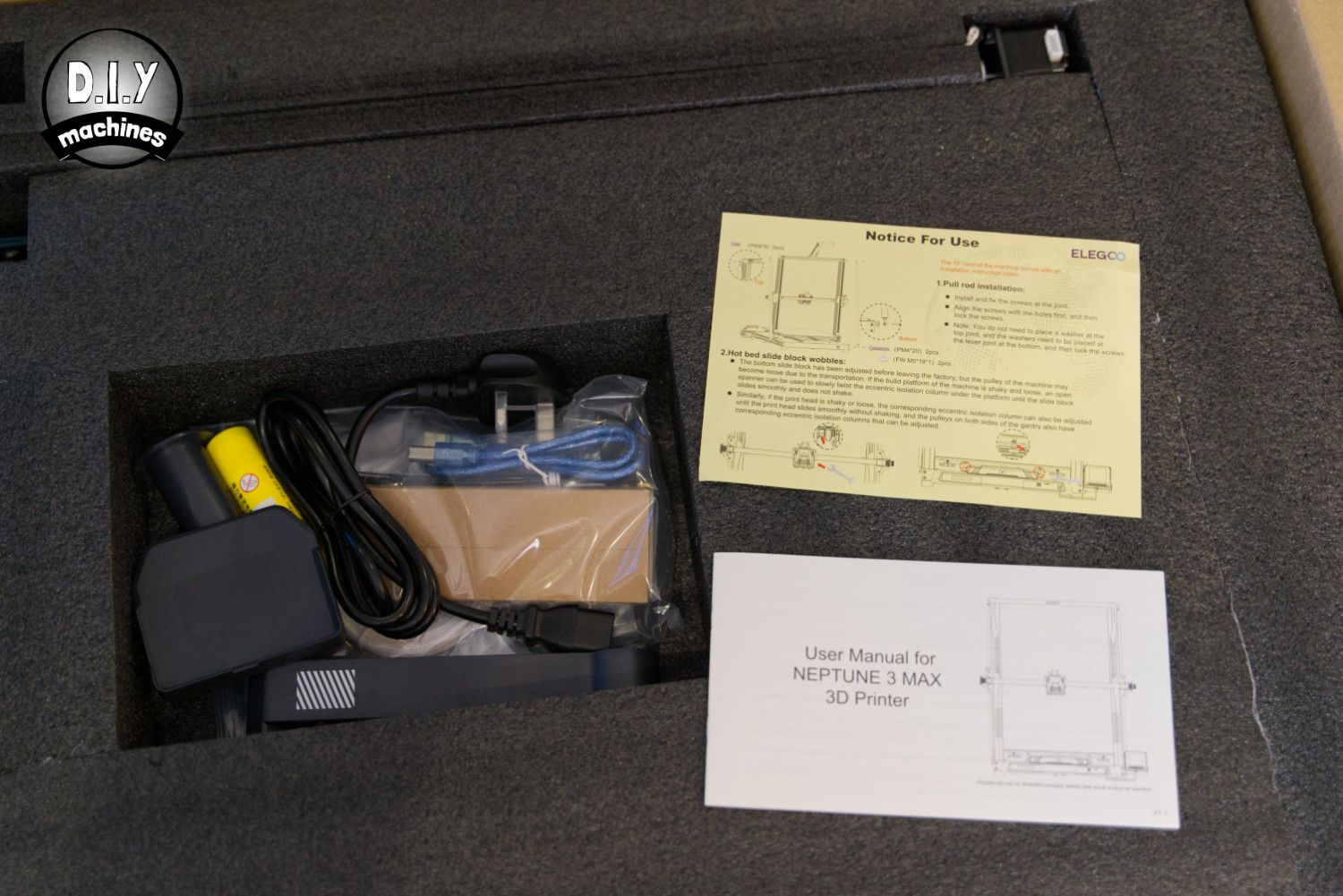

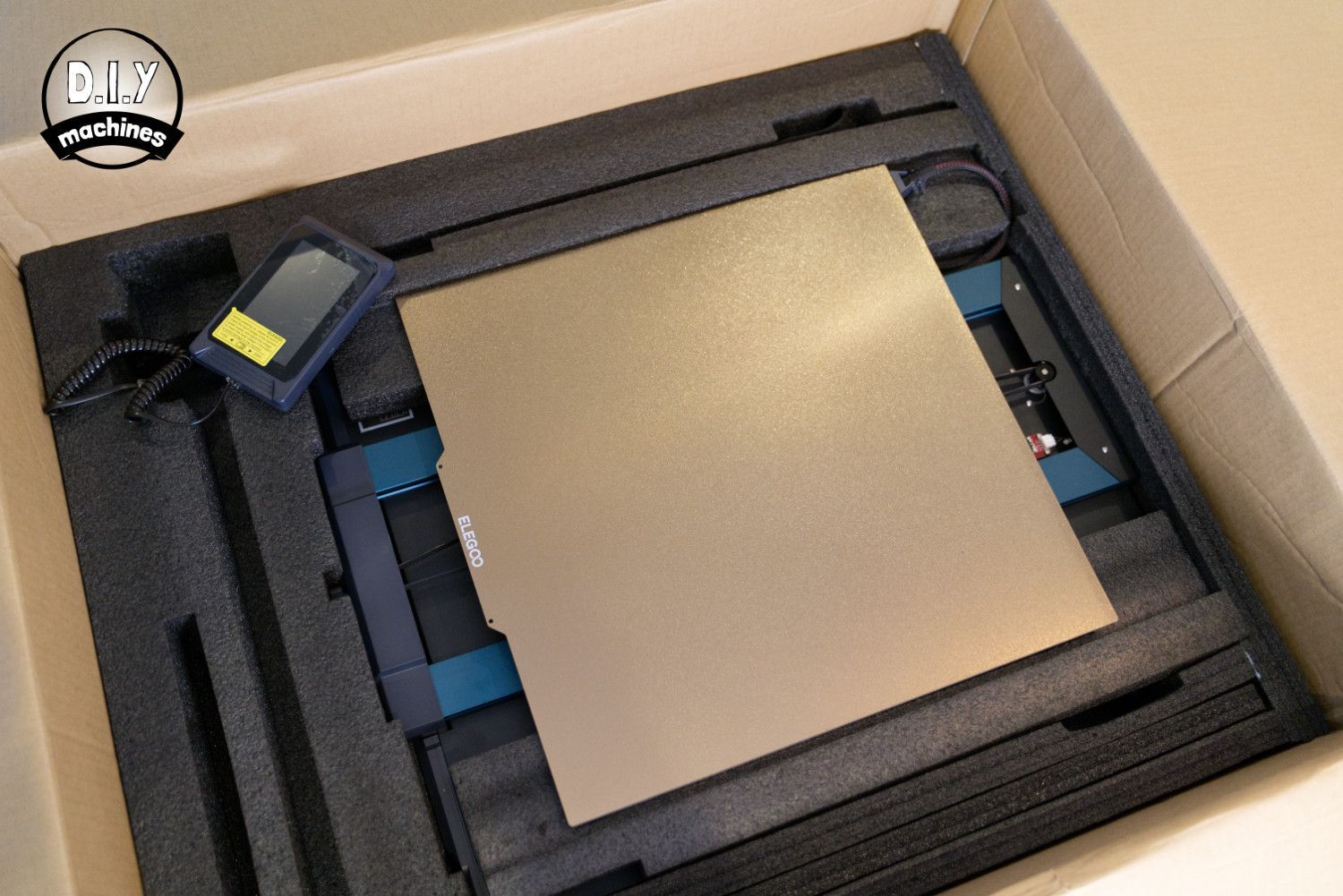

Shipping and Packing

The FDM 3D printer arrived well packed. Plenty of foam defends the contents from any knocks during transit. The main parts of the printer are split between two layers. The box is large given the nature of the printer, measuring 70 x 85 x 29cm.

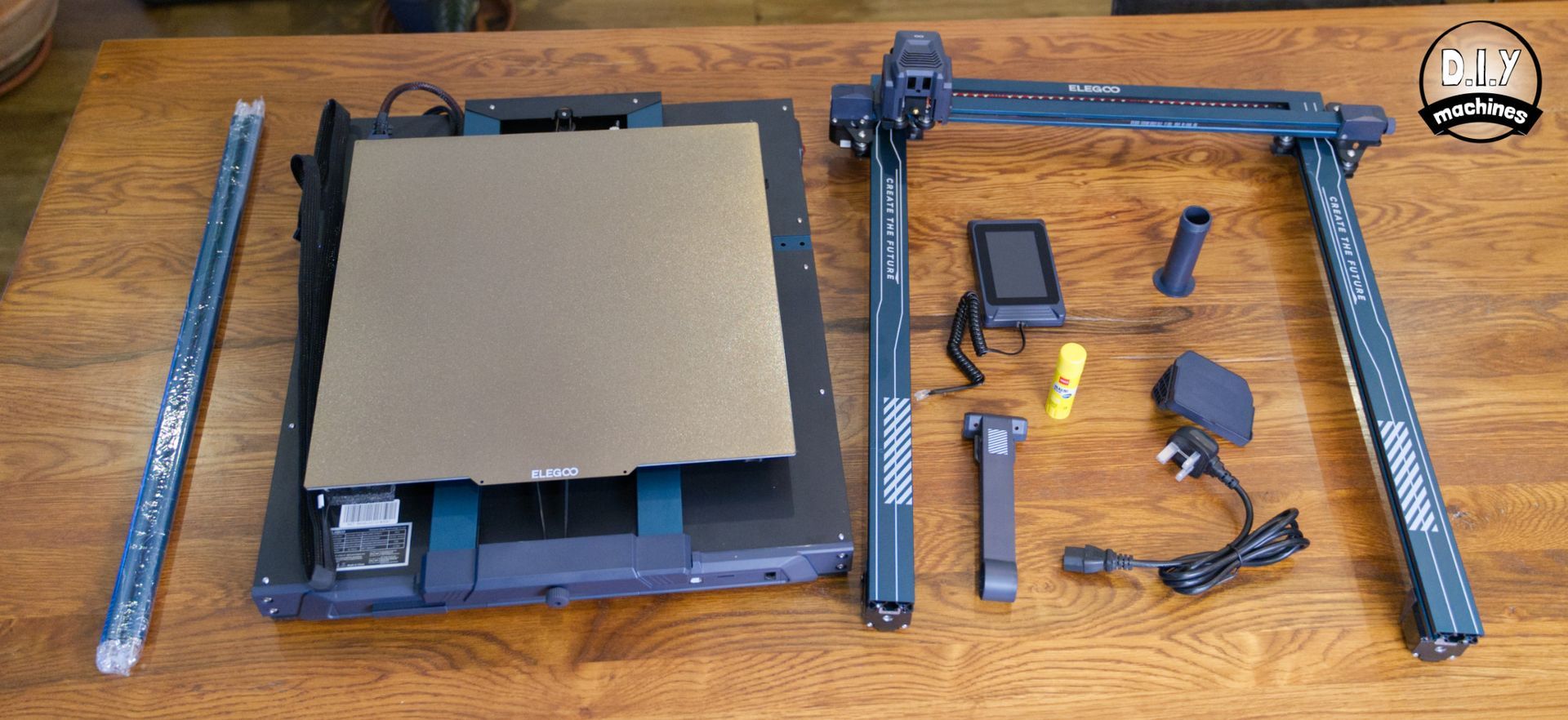

As you can see, this 'kit' comes very nearly entirely assembled. There are only a few parts which are involved in the set-up as you'll see later in the review.

What else is included?

As with all the Elegoo 3D partners I've reviewed, there are plenty of accessories included. More than enough to kit you out if this is your first FDM 3D printer, plenty of spare parts and all the tools you would need to repair and maintain your new machine. The parts list is almost identical to the Neptune 3 Pro with the exception of additional bolts to assemble the vertical braces.

- Print removal spatular

- Spanners for changing nozzle

- Two spare brass nozzles

- Acupuncture Needle (to clear blockages)

- Screwdrivers (Philips and flat head)

- Selection of Allen Keys

- Micro SD / TF Card

- USB Memory Card Reader

- PTFE Tube (Spare)

- Flush Snips / Cutters

- USB Cable

- Sample of PLA Filament

- Cable Ties

- Bolts for assembly

Assembly

This is genuinely so simple it's almost difficult to write about. Essentially the printer arrives in two major halves; the base and the vertical frame. The vertical frame and base are bolted together with four bolts (two each side). This is best done on the machines left side. You can then right the printer and attach the control screen (one cable) and it's mount (three bolts). The spool holder and filament sensor are attached with just three more bolts at the top.

As this machine is so tall it includes two bracing rods which run from the back of the machine to the top. Again, four bolts and a couple of washer and they're installed in just seconds.

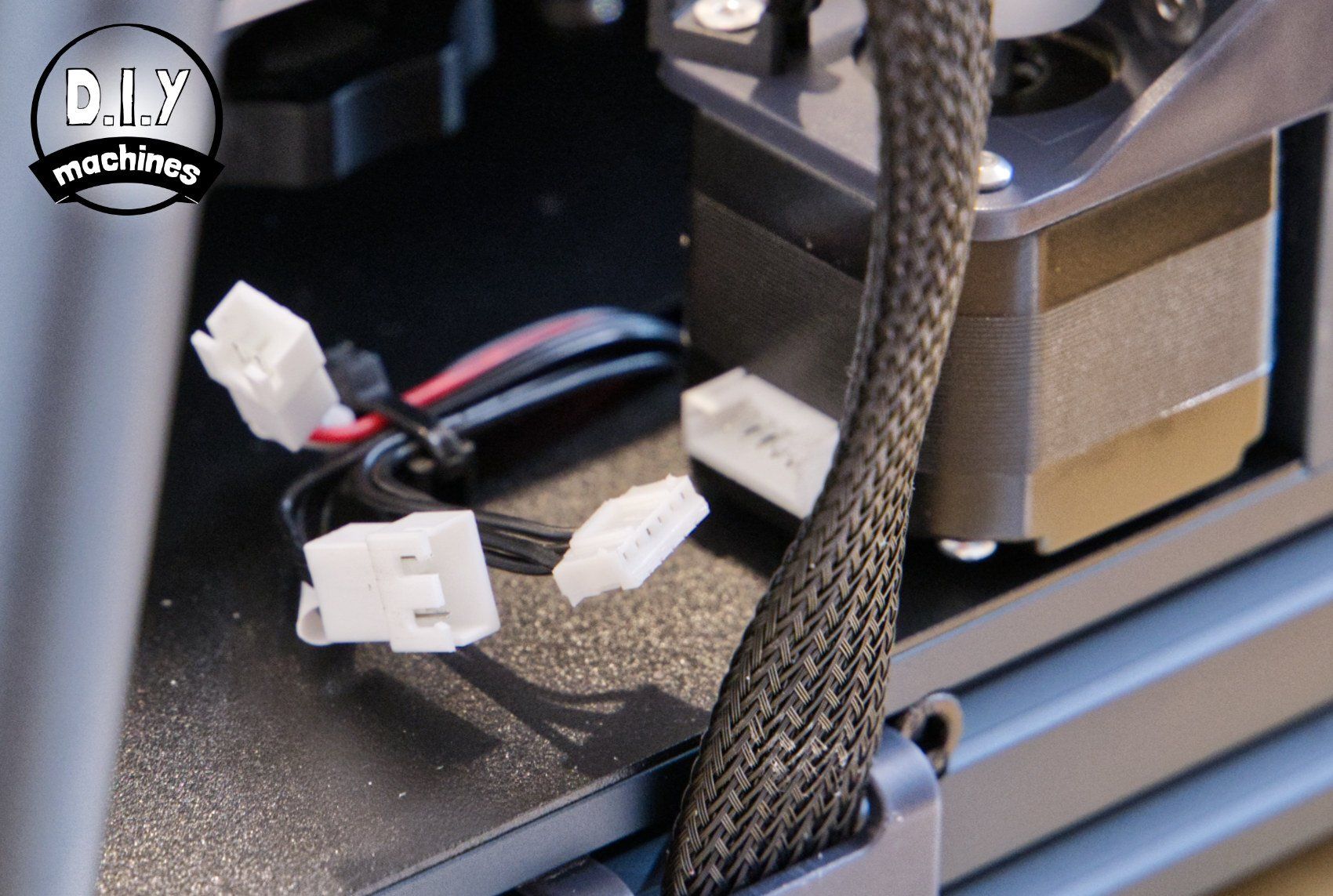

Electronics

All the wiring for the various motors and sensors have already been thoughtfully routed around the machine and present themselves ready for connection alongside the correct component.

To help ensure the correct cable goes to the correct part each one is labelled and uniquely sized connectors are used. I didn't need to consult the instructions save for ensuring I had not overlooked any. I mean it's almost impossible to make a mistake.

Footprint

Let's talk about size again. If you have bought this printer or are considering it then I'm sure you're aware Elegoo didn't call it the 'Max' for no reason. The footprint of the machine where it sits on our work surface measures approximately 64cm deep and 63cm wide (including the touchscreen controller).

However, during use and when printing large objects, the print bed travels beyond its footprint boundary so that realistically you need total clear depth of 90cm. This could be overhanging your worktop at the front by 11 cm and the rear by 15cm to allow for the overextension of the print bed and its power supply cable for the heating elements.

This is no fault of the machine, I just want you to be fully aware of the space required to accommodate the Elegoo Neptune 3 Max.

Instruction manual

The instructions are short and concise, relying on mainly images like an Ikea instruction manual. Processes requiring more detail are explained using a combination of images and words, such as the levelling process. I've included the manual for you to download and look at for yourself if you wanted to.

Elegoo have also included a handy video guide of the assembly procedure which you will find saved on the memory stick included with your new printer. Thanks Elegoo. 😊

First Print

Levelling the Bed

The printer automatically measures the height of the print surface across a grid of 49 unique points and uses this information to calculate a mathematical model it refers to whilst printing to compensate for any warping of the print bed.

Once this automatic routine has completed you need only to set the layer height of the first layer. This simply requires you to continuously slide a piece of common paper back and fourth under the nozzle whilst lowering it with the touchscreen until you feel some slight resistance.

This process was incredibly easy and proved accurate as no further tweaks were required when making the proceeding test prints.

The instructions for levelling the print bed have improved since the Neptune 3 Pro (the smallest of the three machines) - something I called to attention when reviewing the Pro iteration. It shows Elegoo listen and act upon feedback to ensure their development inches closer towards both a fantastic printer and set-up experience.

Loading the Filament

This a process improved since the earlier Neptune 2 iteration of machines. It has become a simple case of passing the filament effortlessly though the detector at the top of the gantry, pressing the comfortable lever on the top of the print head before inserting the filament a few cm's and then releasing.

All that is left to do is to heat the nozzle using the touchscreen (Elegoo provides a handy set of presets for common materials) and pressing load. Done.

Printing the included Sample Model

I always start by printing any bundled models using any bundled filament for the printers first print. It seems fair to use it in its best light.

The Buddha is their chosen test print and as usual I can gladly say that I can't see any glaring issues with the print quality. No surprise there of course. However, printing a model Elegoo have pre-selected and using their supplied filament does not provide ample opportunity to stress the machine. And in this case it certainly doesn't demonstrate the printers ability to create large items!

Click on either of the photos of the sample print to view a larger size and judge the quality for yourself. I am very impressed. It was printed at a 0.15mm layer height. No lifting or warping of the base occurred(they did use a brim in their pre-sliced G-code) and extrusion appears to be consistent.

Printing gets much bigger

Before this printer, the largest thing I had ever printed was a vase on the Elegoo Neptune 3 Plus. (The white one in the images below). To really see just how big I could go I chose another vase, but this time with a geometric pattern.

It measures 21.8cm in width and 36cm in height - it printed first time without hiccups. After the print bed had cooled it was removable from the print bed with a slow pull.

Total time to print was around 37.5 hours and I used 3D Jakes Ultra-satin Gold PLA filament. The image can be clicked on and enlarged to allow for much closer inspection should you wish.

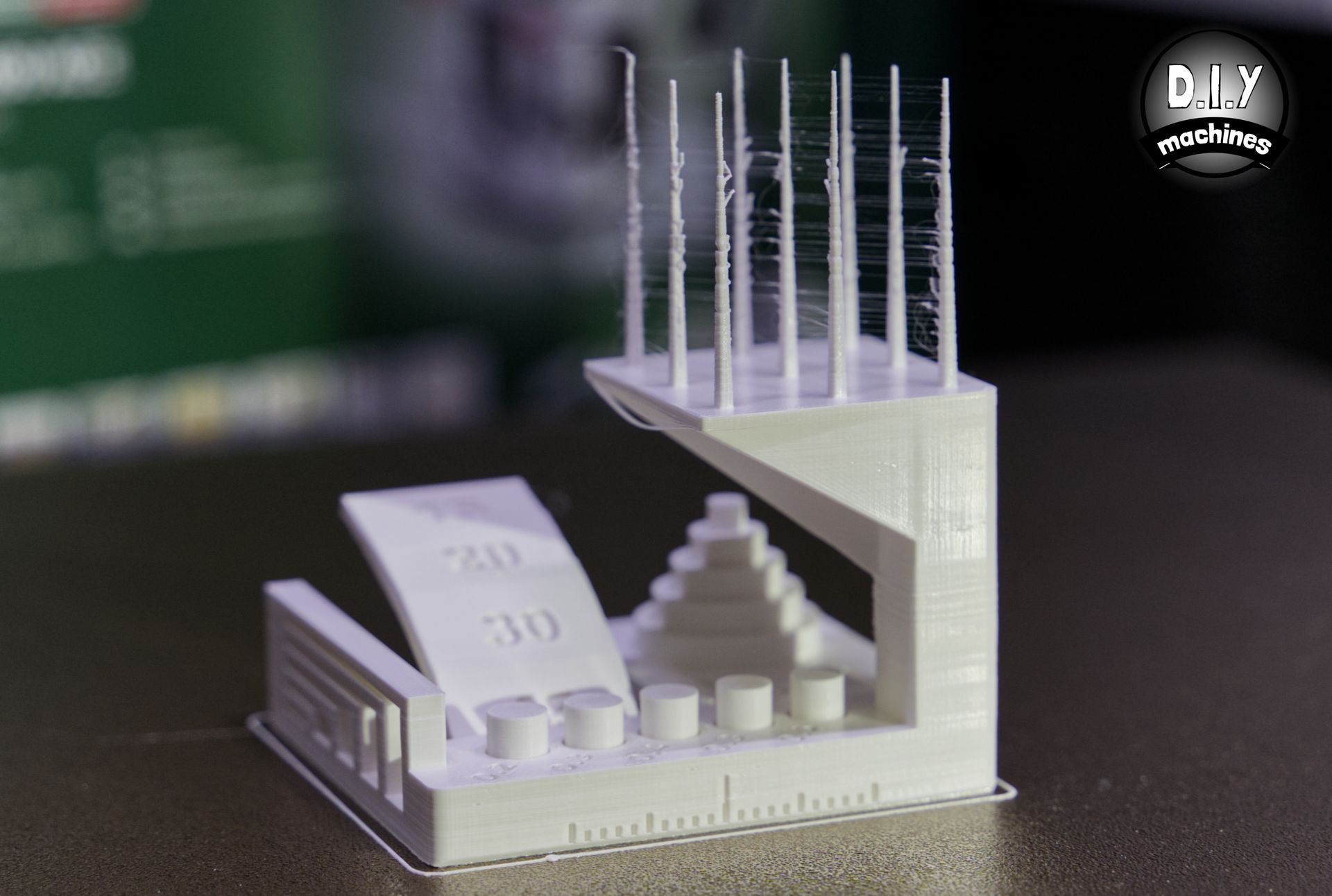

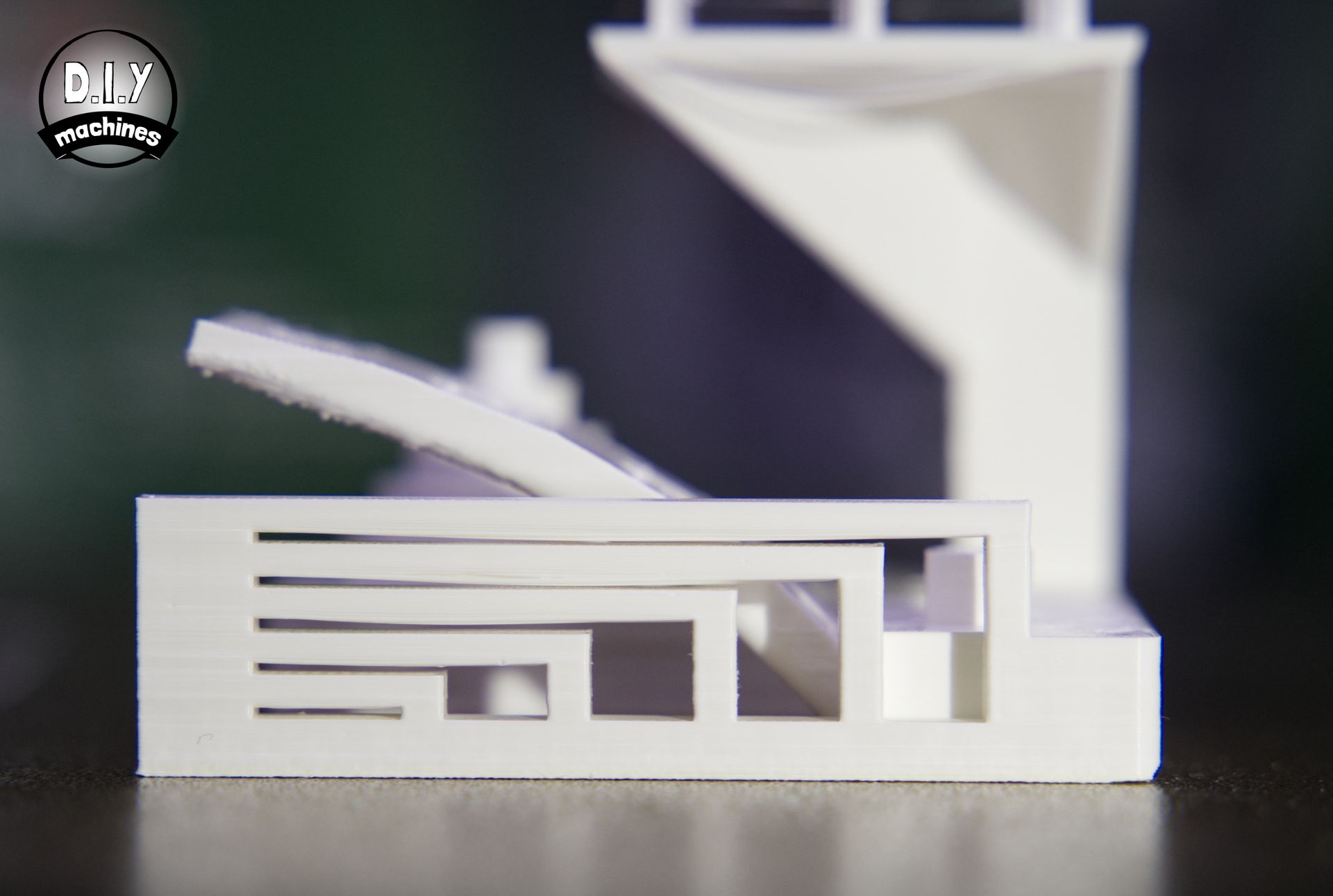

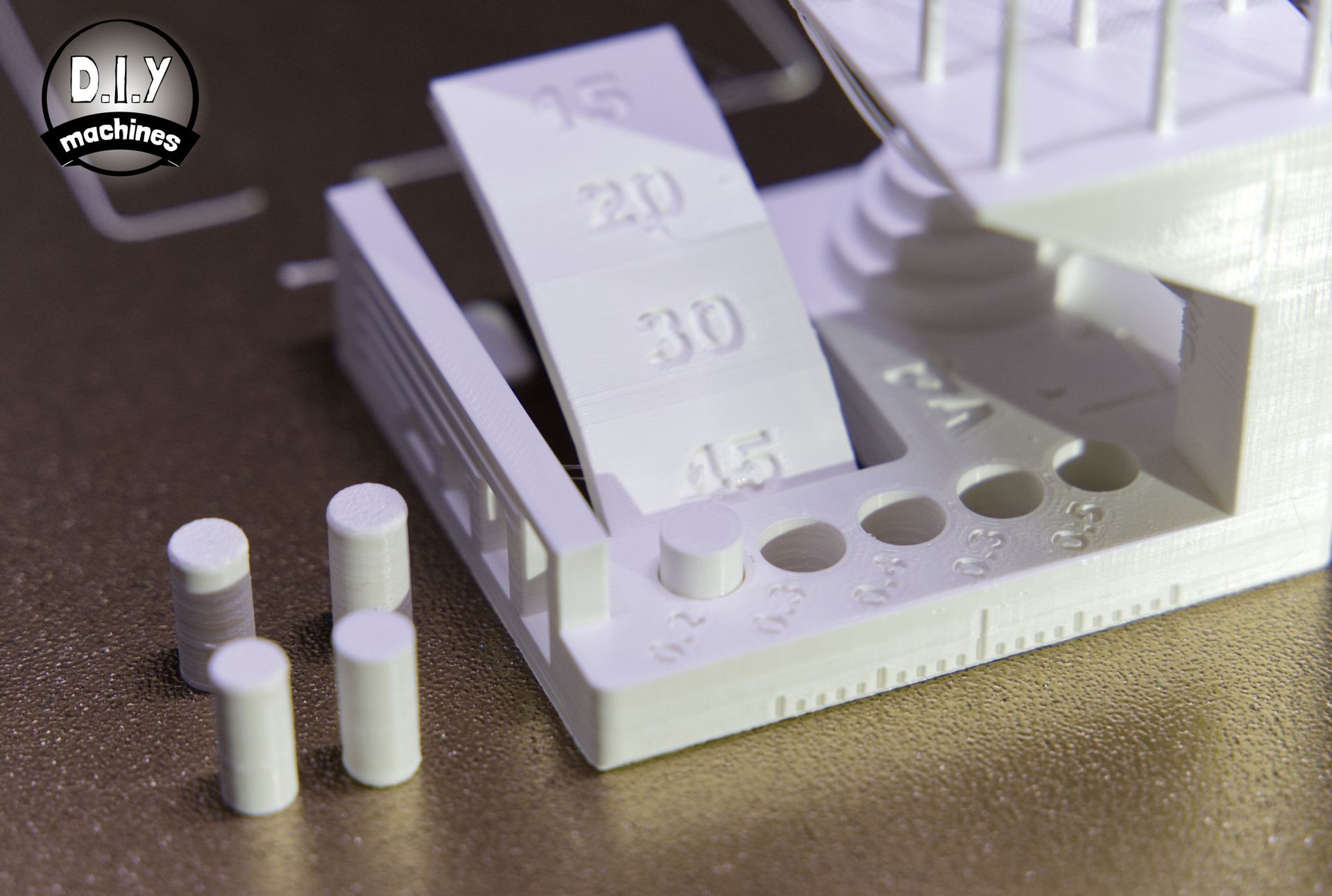

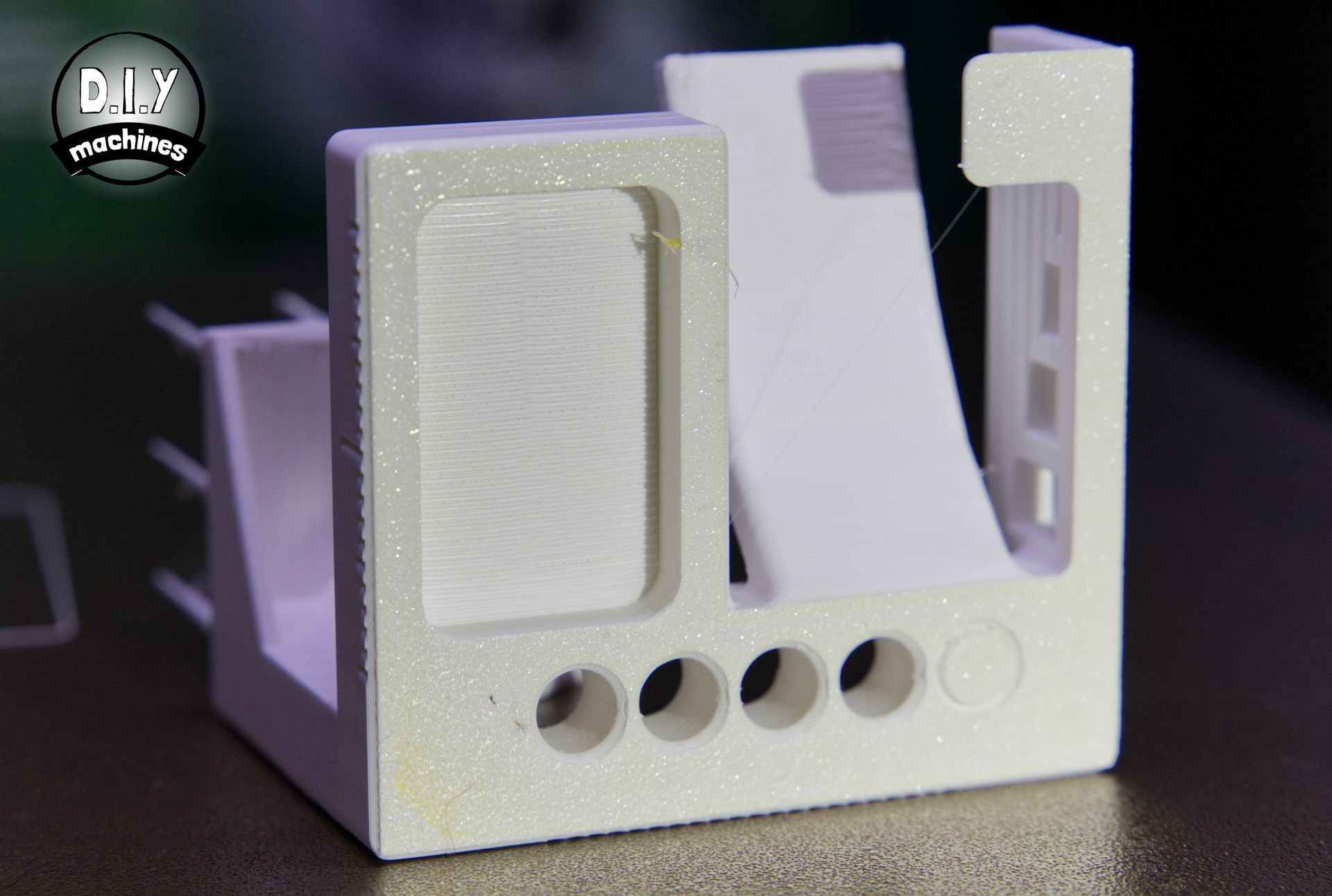

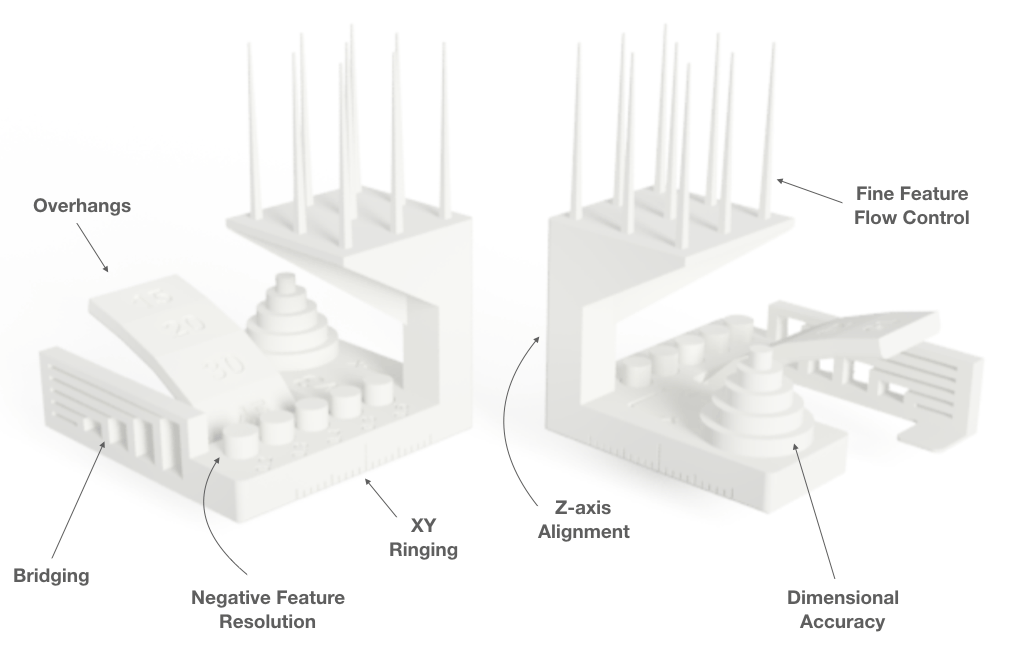

Torture Test

A torture test is designed to stretch the printers ability for several different feature types.

I will print the same one created by AutoDesk and Kickstarter I use on all FDM printers which I review. This allows us to push the limits of the machine such as overhang, bridging, and retraction abilities. It also allows for a fair and convenient comparison.

I have used PrusaSlicer 2.5.1 to prepare the G-code.

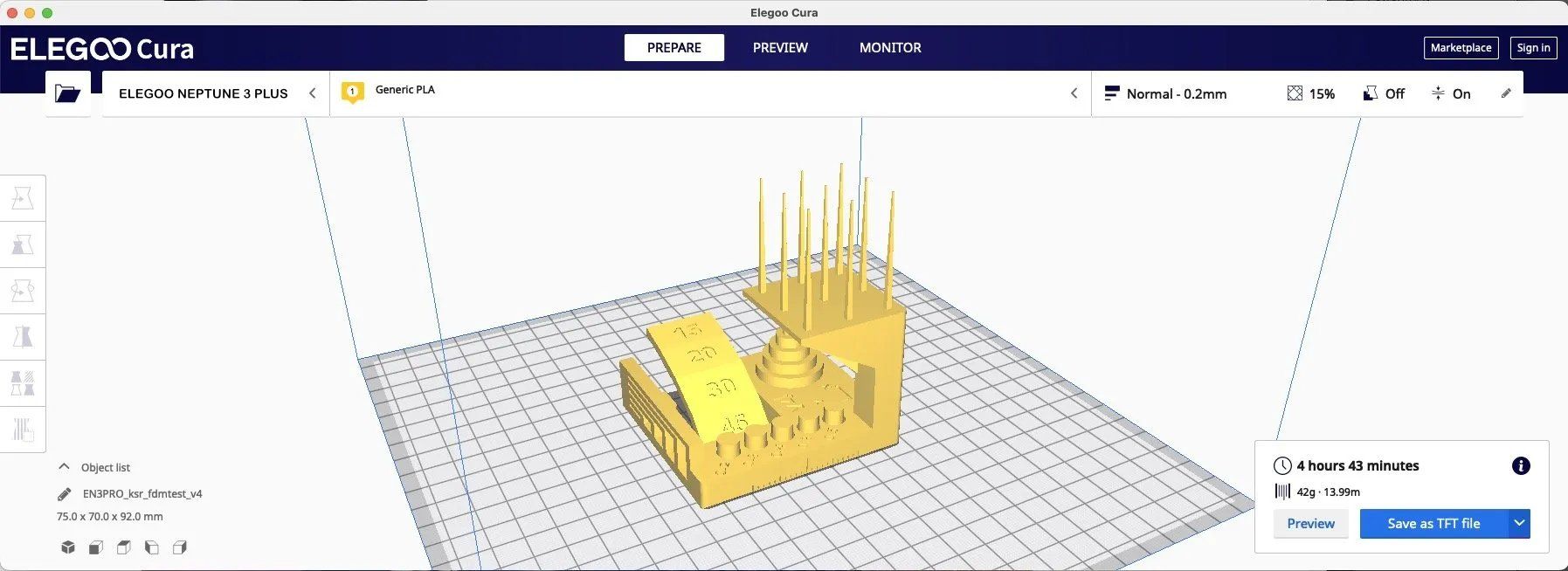

Software

Elegoo have customised a copy of Cura to be used as a Slicer for preparing your prints to be printed. If you're not familiar with Slicing Software then it's the middle stage which takes your computerised 3D models and 'Slices' it into individual layers, usually 0.15mm or 0.2mm in height. Each one of these layers is then prepared as a series of paths for the printer to follow before it raises its print head for the next layer.

The software can have as much an impact on print quality as the hardware itself. They go hand in hand. For example it's the Slicers responsibility to calculate support structures if required and deal with the acceleration and deceleration of the print head in order to balance the need for a desirable print speed without introducing print artefacts into the finished model.

Final Thoughts

I would recommend this printer if you're looking for a very large format FDM printer at a very reasonable price point.

The print size is huge! You don't need to print large prints every time but having the ability to when suitable is very nice. The only two downsides for choosing this machine over the other smaller siblings and using it to print smaller objects is the requirement for more space on your worktop and needing to heat a larger print bed.

So perhaps, if you have the space, it makes sense to go for the larger model and keep you available build volume as big as possible. The addition of the drawer (only on the Max) is very handy - it's simple but super convenient. I would have liked to have seen the ability to attach a larger filament spool to the machine. I have some 2.2kg rolls of filament and when printing models as large as the Elegoo Neptune 3 Max FMD 3D printer allows you're likely to get through much more filament.

The machine itself looks smart. And as for Elegoo themselves, I recently had a problem with a resin printer of theirs and their support representatives where extremely helpful and promptly solved my problem (they sent a new motherboard and some resin for the inconvenience) so I have no issues with the brand.

The Neptune 3 series of machines from Elegoo are solid contenders for the more affordable 3D printing market. And unlike some others budget brands, don't require a slew of upgrades after purchase to ensure good quality prints and ease of use. Something that distorts the value of other printers.

All Rights Reserved | DIY Machines Ltd

-